This text accommodates an affiliate hyperlink.

It’s my objective to be dangerous at many issues. You gained’t discover this slogan on motivational posters. However I counsel everybody to try to be dangerous.

Bushcraft encompasses a myriad of various abilities. There’s room on bushcraft’s broad blanket for monitoring, campcraft, basketry, edible crops, and plenty of different abilities. And a part of the enjoyable is making an attempt all of them!

However not like Ray Mears, I’m dangerous at most issues I attempt. My “Drawer of Bushcraft Errors No One Will Ever See” has change into a complete closet! But it surely doesn’t cease me from making an attempt new abilities. Perhaps, in opposition to all odds, I’ll uncover that I’m really good at one thing.

On this spirit, I got down to forge my first knife. The Talmud states, “End up a trainer.” And I discovered an excellent one. San Francisco State College affords a bladesmithing class at their Sierra Nevada Area Campus. And the trainer, Sam Farnworth, is the actual deal!

I first met Sam as I walked from my tent to the cafeteria. He was mendacity on an animal pores and skin carving a spoon. Sam has a pleasing outlook and is affected person along with his college students. He explains clearly, and re-explains if college students have bother understanding. Greater than 30 years youthful than me, I’m taken with Sam’s vitality and enthusiasm.

Dare Mighty Issues.

– Teddy Roosevelt

Methods to Make A Knife

The method is straightforward in idea: Forge the knife, refine it with a file, warmth deal with the steel, sharpen the blade, and vogue a deal with. Through the class I make a carving knife, that I title “Little Chip,” and a spoon gouge that I christen, “Gougezilla!”

Forging the Knife

The forges and anvils are arrange beneath a tarp to guard us from the solar.

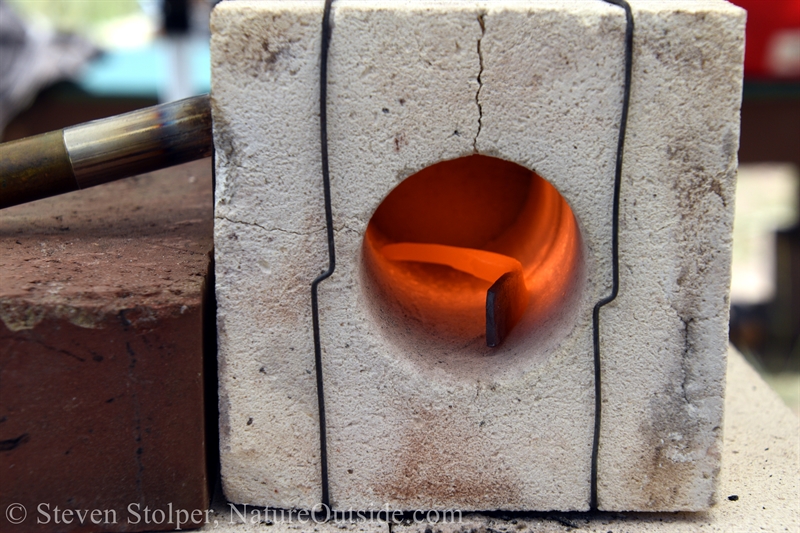

Every forge is a propane blowtorch that heats a chamber constituted of hearth bricks. A downside of those makeshift furnaces is that they don’t work effectively at excessive altitude. Our class takes place at an elevation of 6,000 toes within the Sierras. So every pupil has an extended wait for his piece to warmth to the 1,800-degree Fahrenheit working temperature.

The forge is a propane blowtorch that heats a chamber constituted of hearth bricks.

We insert and take away our items by the round opening.

We’re making our knives from W1 Device Metal. It’s a excessive carbon, water hardened metal with a excessive tensile energy and hardness. Surprisingly, the cylindrical blanks we use are solely three inches lengthy. However that’s advantageous as a result of the fabric will broaden as we hammer it.

Our blanks for making knives and spoon gouges.

We warmth our items within the forge till they glow. Then we work the glowing steel by holding it with tongs and hammering it in opposition to an anvil. One enjoyable truth I discovered in regards to the anvil is that its edge has a special radius alongside its size. I can curve the steel to completely different radii by hammering it in opposition to completely different components of the anvil’s edge.

Our instruments – Anvil, tongs, and cross pein hammer

Two college students share a forge and an anvil. Whereas one pupil works his piece on the anvil, the opposite’s reheats within the forge. When the temperature of our piece cools too low to work, we change it within the oven and swap positions with our accomplice. If we work steel that’s too cool, we are going to introduce fractures that may trigger it to crack throughout warmth remedy.

Heating our blanks

A pupil removes his piece after it reaches working temperature.

The forges attain a temperature of two,000 levels Fahrenheit. After we take away our piece it’s glowing at 1,800 levels Fahrenheit.

A pupil flattening the blade of his knife.

My spoon gouge heating within the forge. I’m heating the tang to form and refine it.

It’s no coincidence that stereotypical blacksmiths are typically massive burly males. It takes a stunning quantity of power to hammer the glowing steel into form. And whereas I can strike laborious sufficient, I discover it troublesome to take action whereas sustaining the place of the tongs in my different hand. And when I attempt to be correct with my blows, I don’t generate sufficient power to deform the steel they approach I would like. Because of this I’m going by a a number of irritating cycles of taking the piece out of the furnace, making somewhat progress, after which returning it to the forge to reheat. Sam, our trainer, can pound the piece into the proper form in a single go.

A Break from the Warmth

Once I work with the forge, I put on denim denims and a long-sleeve cotton canvas shirt. It’s because hanging the steel with our hammers can generate “scale.” These are small items of steel that break off the piece after we strike it and oxidize in fiery sparks. In the event that they land on naked pores and skin, they will trigger minor burns. So whereas we forge our items most of us hold our pores and skin coated and put on eye safety.

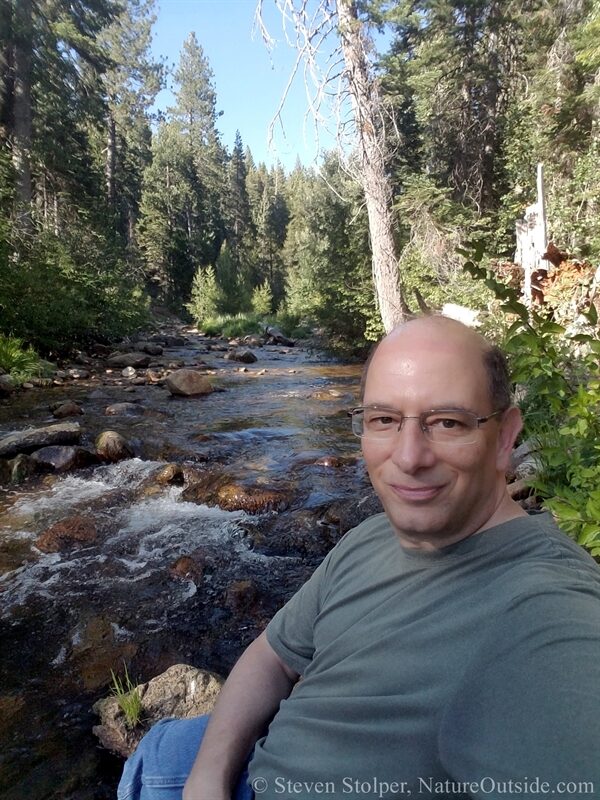

Forging our knives is scorching work. And as we labor, the summer time air temperature reaches 93 levels Fahrenheit within the shade. There may be additionally a wildfire burning close by. This mixture of excessive warmth and the smoky air compels us to take a well-earned break on the close by Yuba River.

Bladesmithing is scorching work when the air temperature is within the nineties.

Soaking within the Yuba River.

Submitting the Blades

After we form the blades on the anvil, we anneal them. Annealing entails heating the metal to a excessive temperature after which cooling it slowly. Annealing removes the stresses we launched whereas hanging the steel with our hammers. It additionally makes it “softer” in order that we are able to file it extra simply.

Our trainer, Sam, makes use of a chainsaw to make a v-shaped minimize right into a log. This permits us to clamp our blade to the stump and have each palms free to file.

Our submitting instruments. Discover how the log is carved in order that we are able to connect the clamp.

The knife is able to be filed. Notice the piece of Alder I chosen to change into the deal with.

I’m going to file the convex (outer) fringe of the spoon gouge. Having a single bevel on the surface of the gouge permits me to maintain it sharp over its lifetime. Notice the piece of Alder I chosen to change into the deal with.

Sharpening the Blades

After we profile the blade with the file. Our subsequent job is to mood the metal. We warmth the steel to excessive temperature after which shortly cool it by quenching it in water. Tempering makes the metal more durable – it could possibly stand up to higher forces with out breaking or deforming.

But when we made any errors in the course of the forging, the knife can snap or shatter when it’s quenched. I maintain my breath by your complete course of.

The tempered metal has a definite coloration that lets us know we have been profitable.

After we mood our blades, we sharpen them on numerous whetstones. That is by far the longest and most tedious a part of the knife making course of.

Though my blade is small, I choose to provide it a Scandinavian grind to make it simpler to sharpen sooner or later. It’s additionally an excellent grind for carving wooden.

The Handles

For the handles, I harvest white alder (Alnus rhombifolia), additionally referred to as the California alder. Alders are members of the birch household (Betulaceae) and develop natively in riparian habitat.

The Alder taught me a bushcraft lesson. I had been passing stands of Alder for years with out paying them any consideration. Now that I understand I can carve them to make handles, I see them in a special gentle and can by no means overlook them once more.

I additionally discovered the worth of an excellent instrument. The saws offered to the scholars have been flimsy and didn’t minimize effectively. Thankfully, I carry a Bahco Laplander within the trunk of my automobile. I take advantage of it to reap pure supplies and take away obstacles after I’m driving on unmaintained roads. The noticed is light-weight and transportable however very strong. Better of all, it cuts on each strokes. It made straightforward work of the Alder and I ended up lending it to a number of different college students.

Whereas the steel items are nonetheless scorching from the forge, I power them into pilot holes I drilled into the harvested wooden. This burns a “customized match” for the tang in every deal with.

After eradicating the blades, I carve the wooden to make handles that really feel good in my hand.

I connect the finished handles to the tangs utilizing epoxy, coloured black with charcoal from our campfire. For my gouge, I take advantage of charcoal from Redwood bushes close to my house that burned within the CZU wildfire.

I defend the wood handles by rubbing them with Danish Oil. That is completely different from the polyurethane end I take advantage of for my firesteels. It’s good to attempt a brand new strategies and examine them with others I’ve used.

They’re Mine – They’re Particular!

Listed below are the completed knife and gouge.

Listed below are the completed carving knife and gouge.

These are small instruments for spoon carving.

You may see the sting on the outer floor of the spoon gouge.

Right here they’re alongside professionally made instruments from my workshop.

“Little Chip” above and a professionally made knife under.

A professionally made spoon gouge above and “Gougezilla” under.

I need to level out that though they don’t seem to be as “polished” because the skilled instruments – they work simply advantageous. And they’re particular as a result of I made them.

They are going to give me monumental pleasure for a few years to return.

Associated Articles on NatureOutside

10 Tools Items for Bushcrafters, Nature Lovers, and Folks Who Love the Outdoor

You’re no Ray Mears, and Right here’s Why!

Methods to Make a Customized Firesteel with out Fancy Instruments

For enjoyable details and helpful ideas, be a part of the free NatureOutside E-newsletter.